Food & Beverage

Tech-Weld Food Grade Stainless Steel Tubing

Trusted by Leading Food & Beverage Companies

With over a decade of experience in the food and beverage industry, we understand the unique requirements of food and beverage companies, including food-grade stainless steel tubing.

The food and beverage industry trusts Tech-Weld as a reliable source to bring the tubes, tanks, cones, and weldments of food and beverage companies to life.

Tech-Weld has a specially developed, state-of-the-art quality lab that contains industry-leading equipment designed to ensure precise part specifications. Our tubes for food and beverage needs are offered in custom sizes in the following ranges:

Small Diameter Tubes, Tanks, and Weldments

- Diameter – 3″ to 9″

- Lengths – Up to 60″

- Thickness – Up to .125″

Large Diameter Tubes, Tanks, and Weldments

- Diameter – 10″ to 36″ with capabilities to do larger.

- Lengths – Standard tube lengths are 144″. We can easily produce tubes up to 288″ or longer.

- Thickness – Up to .188″

Food Grade Stainless Steel Tubing Applications

- Dairy production

- Sugar processing

- Meat processing

- Fish processing

- Distilleries

- Breweries

- Bread and milling

- Cannabis industry

- Cone hoppers

The food and beverage industry requires metals that won’t react chemically. Metals must meet FDA standards to keep food and beverages safe for consumption. That’s why food grade stainless steel is very often used. Stainless steel isn’t chemically reactive and is generally resistant to acidic corrosion as well, making it an excellent choice. We also can design tubes in any metal requested.

Serving Our Customers in the Food & Beverage Industry

Tech-Weld is proud to offer high-quality tubing products, including custom tubes, tanks, cones, and weldments, that tube mills simply cannot provide. We perform our services within tight tolerances. We don’t ship our custom food and beverage products until they have been thoroughly tested. If we aren’t satisfied, the product won’t leave our facility.

We support each customer throughout the entire production process, and our knowledgeable staff is available to answer any questions and concerns. Whether you’re a customer or a supplier, Tech-Weld’s goal is to get you the highest quality product in the shortest amount of time.

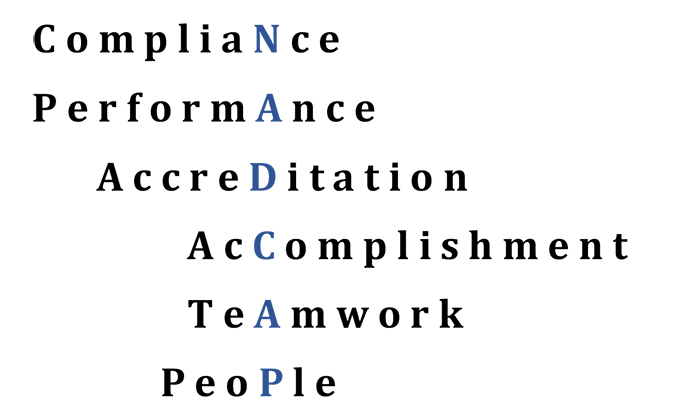

Tech-Weld has continued to demonstrate our ongoing commitment by obtaining the highest level of certification. Tech-Weld is NADCAP (Welding) accredited, ISO 9001/AS9100 certified, and ITAR registered.

NADCAP stands for:

A Commitment to Excellence

Tech-Weld’s unwavering pursuit of excellence is evident in our dedication to maintaining quality throughout every facet of our operations. From our skilled professionals to our state-of-the-art equipment, we prioritize consistency and precision at every step.