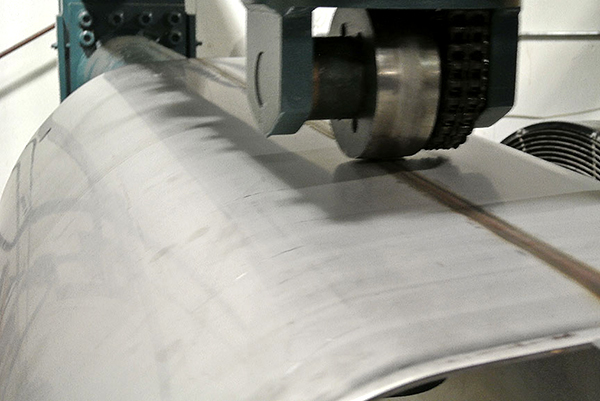

Planishing Services

Function of Planishing

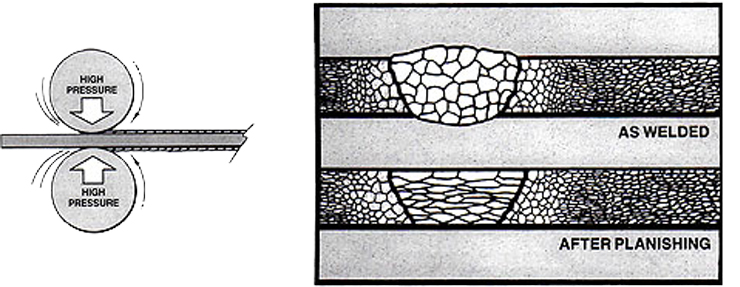

Planishing is a highly effective and efficient technique used to reduce weld build-up and enhance the surface finish of welded areas. It shares similarities with the cold rolling process employed in steel mills; however, it’s targeted to the localized region of a weld. By utilizing controlled force, planishing offers several advantages that contribute to improved weld quality and appearance.

Advantages of Using Planishing Services:

- Accelerated Weld Build-Up Reduction: Planishing can significantly reduce weld build-up at a much faster rate compared to traditional grinding methods. This speed translates to increased productivity and reduced operational time.

- Superior Surface Finish: A major benefit of planishing is its ability to yield a smooth, cold-rolled surface finish. This aspect is particularly crucial when working with stainless steel products that require a polished appearance.

- Enhanced Weld Metallurgy: The process of planishing involves cold working the “as cast” weld structure, which can lead to improved metallurgical properties within the weld area. This can result in enhanced structural integrity and performance.

- Weld Spread and Shrinkage Compensation: Planishing causes the weld to spread out, often offsetting the initial shrinkage that occurs during the welding process. This effect helps to maintain the original dimensions of the workpiece.

- Strength and Cosmetic Blending: As the planishing force is applied, the weld bead is not only flattened but also blended seamlessly into the surrounding base metal. This creates a cosmetically smooth transition while retaining the strength of the weld.

- Elimination of Weld Crown Reinforcement Grinding: The substantial force generated during the planishing process—up to 15,000 pounds (6,804 kgs)—eliminates the need for grinding the weld crown reinforcement. This saves time, resources, and labor associated with additional grinding steps.

- Suitable for Various Metals: Planishing is versatile, applicable to both ferrous and non-ferrous metals. This adaptability makes it a valuable technique across a wide range of applications.

- Flat Seam Appearance: One of the primary goals of planishing is to blend the weld bead seamlessly with the base material. This creates a flat seam appearance that enhances the visual aesthetics of the welded piece.

How planishing works

In essence, planishing services at Tech-Weld offer a comprehensive solution to multiple challenges associated with welding, including excess build-up, surface finish, metallurgical properties, and appearance. Planishing’s ability to combine efficiency, quality, and versatility makes it a go-to method for achieving exceptional results in various welding applications. Whether working with ferrous or non-ferrous materials, planishing ensures a consistent and polished outcome that aligns with both functional and aesthetic requirements.