Tech-Weld Welding Capabilities

Welding Capabilities: Three Generations of Expertise

At Tech-Weld, welding is both the cornerstone of our manufacturing process and a testament to our generation-spanning legacy. We have honed our welding expertise to perfection, becoming a trusted partner in surpassing expectations with our welding solutions. Our commitment extends beyond expertise; we also take pride in meticulously maintaining our machines to ensure flawless part production. Our highly experienced team of welders can adeptly meet various welding procedure specifications tailored to your precise needs. For us, welding isn’t merely a process; it’s an integral element in nearly every product we manufacture. Combined with our NADCAP accreditation for welding and our certifications for ISO 9001 / AS9100, our welding capabilities demonstrate our ongoing commitment to quality by satisfying our customer requirements and industry specifications.

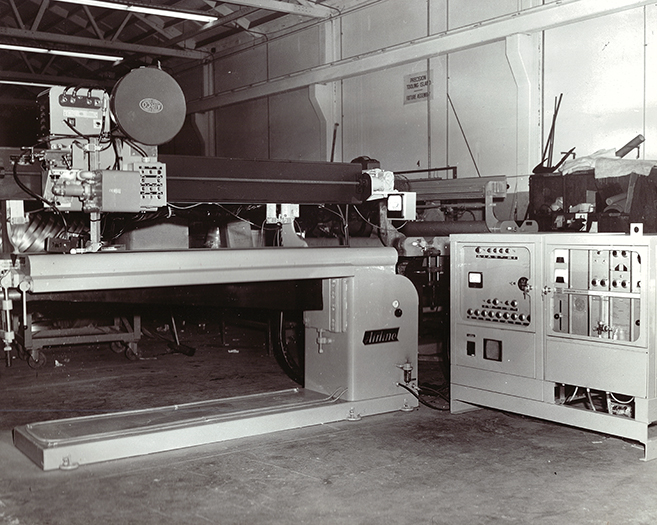

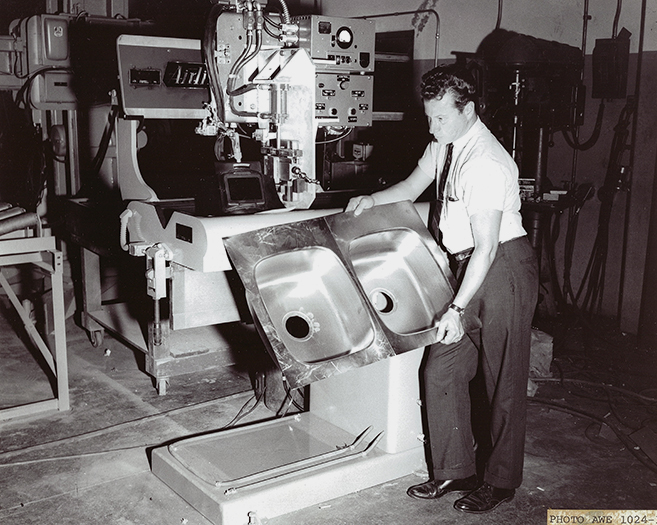

Seam Welding Stations

Our knowledge and experience of seam welding is in its 3rd generation. The process of joining workpieces made of similar or dissimilar materials along a continuous seam is known as seam welding. Our state-of-the-art seam welding equipment is CNC controlled, calibrated for the highest quality seam welds. With just a single pass, our automated seam welders can produce high-quality welds with complete joint penetration. Tech-Weld takes pride in maintaining all of our machines to ensure your parts come out consistent every time. Welding is a key element for nearly every product that we manufacture. With many years of experience, our skilled welders proficiently qualify for almost any welding procedure specifications to meet your part specification needs. Our welders can weld a variety of materials and processes to meet any of your project requirements.

First generation of welding

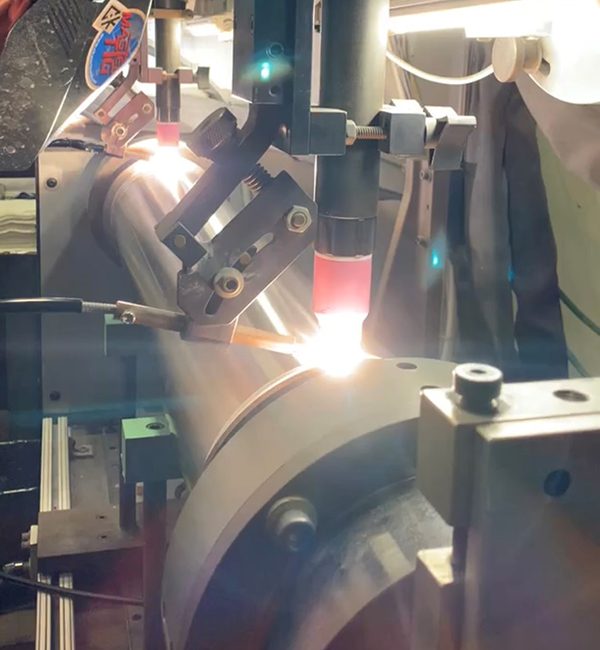

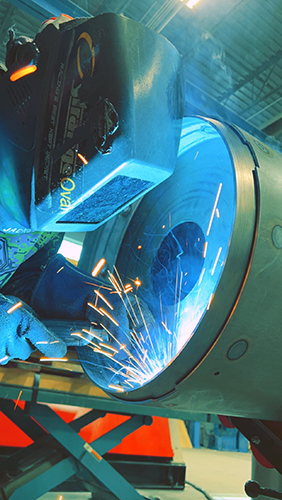

Circumferential Welding Stations

Our custom built automated circumferential welding machines can perform two welds at a time, providing unparalleled consistency in the weld. The cold wire feed TIG welding operation is precise and gives us the ability to tightly control all essential variables of the welding process. Our automated process guarantees precise and airtight welds, making it ideal for applications where leak-proof joints are critical. Tech-Weld will work with our customers to create custom tooling to achieve high welding speeds without compromising accuracy, ensuring quicker turnarounds for all your project needs. Our calibrated equipment and our computer-controlled welding process allow us to deliver the highest quality of consistent circumferential welds every time.

Manual MIG and TIG Welding Stations

Our MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas) welding stations are set-up with lathes for welding end caps, studs, fittings, and any type of component you would need for your tank and weldment needs. Tech-Weld stands as a benchmark of mastery. MIG welding’s speed and versatility meet TIG welding’s precision and adaptability. Together, they embody the modern art of metal fabrication, offering solutions that cater to diverse industries and applications.

Skilled Welders and Unmatched Proficiency

Our team at Tech-Weld consists of seasoned welders with years of industry experience, a testament to their unmatched proficiency. This wealth of knowledge empowers us to seamlessly navigate a wide spectrum of welding procedure specifications, guaranteeing a seamless alignment between welding processes and the exact specifications of each part. Our welders are well-versed in a multitude of materials and welding techniques; this adaptability enables us to tailor our solutions to meet the unique requirements of each project. Whether it’s the complexity of design, the demands of specific materials, or the standards of various industries, our welders deliver precise and tailored outcomes within our fully air-conditioned facility. We’ve developed an environment that fosters excellence in both our welders and welding processes, upholding rigorous maintenance and calibration practices to ensure consistent quality parts every time.

Our welders can weld to almost any code specifications to fit your needs. Some examples include AWS D17.1, AWS D1.1, AWS D15.1, AWS D9.1, AWS B2.1, and AWS D1.6.

Customer-Focus and Our Commitment to Excellence

The cornerstone of Tech-Weld’s philosophy is a resolute focus on the customer. We’re not just listeners; we’re agile problem-solvers, ready to adapt to evolving needs and to deliver timely, cost-effective solutions. Our commitment to precision and customer satisfaction forms the bedrock of our approach. Tech-Weld’s unwavering pursuit of excellence is evident in our dedication to maintaining quality throughout every facet of our operations. From our skilled professionals to our state-of-the-art equipment, we prioritize consistency and precision at every step.

Contact Us

Experience the highest level of precision welding and quality with Tech-Weld. Whether you require airtight joints, rapid project completion, or versatile welding capabilities, we have the expertise and state-of-the-art equipment to deliver beyond your expectations. Contact us to discuss how we can contribute to the success of your projects.